Introduction

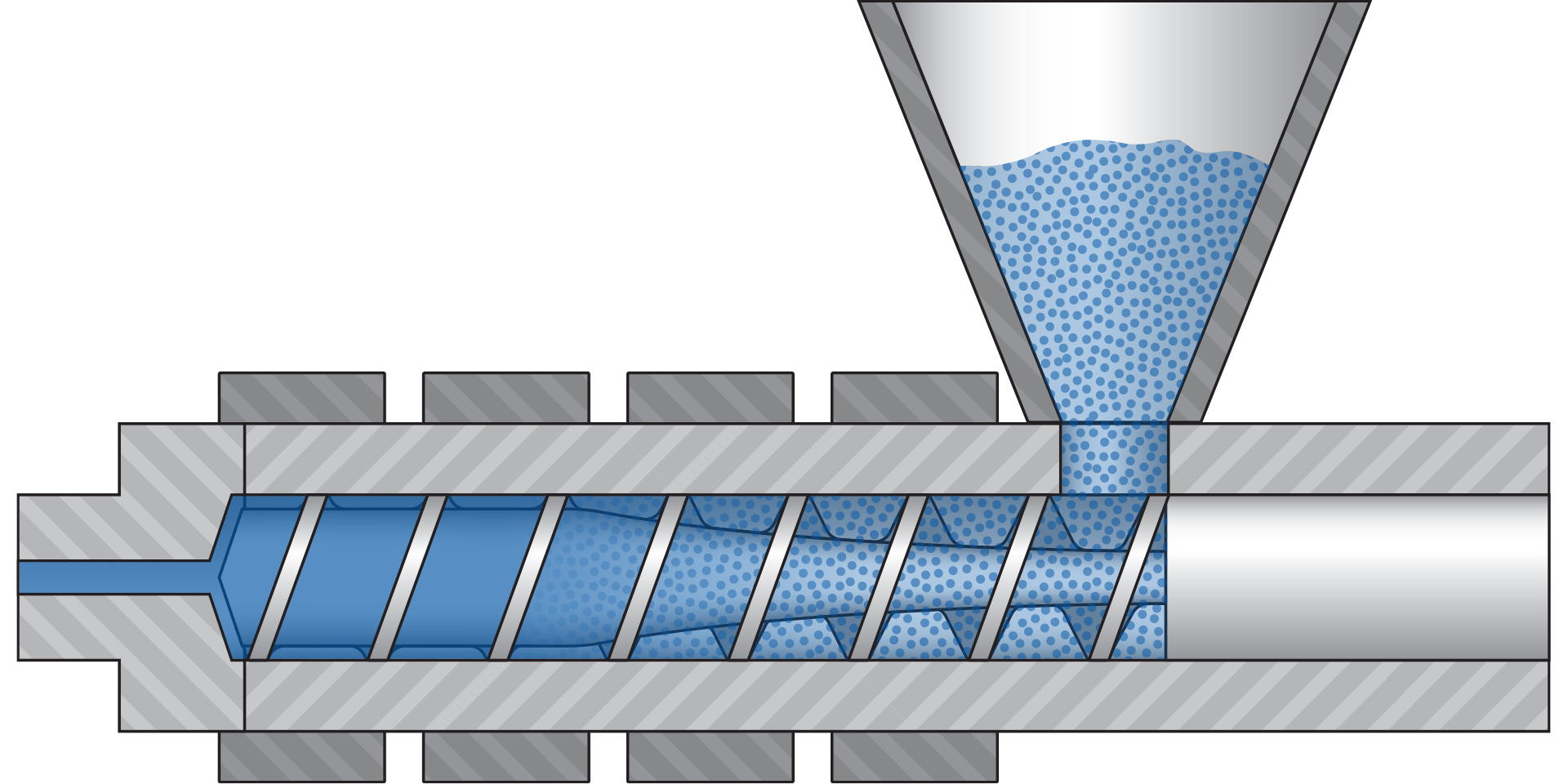

Extrusion Operator Guide

Plastics Materials, Processing, Troubleshooting, Drying, Purging, and Other Practical Information — authored by Daniel Stephens

Plastics is a sophisticated and diverse discipline. To excel, you need a good grasp of a wide range of concepts and data. The purpose of this guide is to provide extrusion operators with information that can help them to process, document, and troubleshoot more effectively.

While Routsis Training hopes you find this information useful, it should not be considered a substitute for continuous education. Techniques and technologies are advancing rapidly throughout the industry, which is why top-performing professionals turn to Routsis Training to keep enhancing their skills.

We invite you to further explore the topics covered in this guide through the comprehensive array of online training programs we provide at www.traininteractive.com.

Disclaimer

This reference guide contains general recommendations intended solely for informational use within the plastics extrusion industry. It is not intended to serve as engineering advice.

The information contained herein is based on published information, knowledge, research, and experience which are presumed to be accurate and complete to the best of our ability. All information is based on averaged data of commonly available grades of plastics and current industry practices at the time of this printing. Therefore, it is the user’s responsibility to review and confirm all design, calculations, and processing decisions.

You should always design and process using the recommendations that are provided by your raw material supplier, resin distributer, machine and equipment supplier(s).

Each material, machine, and process have their own set of influencing factors and, therefore, may or may not comply with the information provided in this guide. Routsis Training, LLC will not accept responsibility or liability for use of the information contained within this guide.

Contact Us

Routsis Training, LLC

379 Amherst Street PMB 233

Nashua, NH 03063 (USA)

phone:(978) 957-0700

website:www.traininteractive.com

store:store.traininteractive.com

email: info@traininteractive.com

Understanding Plastics

General Classification of Polymers

In the industry, plastics are often referred to as polymers, and the actual plastic pellets are commonly referred to as resin or raw material. A polymer is classified using different criteria and is considered to be either; natural or synthetic, thermoset or thermoplastic, and amorphous or semi-crystalline. Natural polymers are those found in nature, such as rubber, cotton, and silk. Plastics processing typically calls for the use of man-made synthetic polymers such as polyethylene, ABS, and nylon.

Thermoplastics vs. Thermosets

Polymers get their strength from a process called polymerization. During polymerization, small molecules called monomers combine to form long polymer chains. Thermosets are polymerized during processing while thermoplastics are polymerized before being processed. During processing, the polymer chains in thermosets fuse together, or cross-link. Once these polymers cross-link, they undergo a chemical change which prevents them from being melted and reprocessed. An egg is an example of a natural polymer which thermosets. Once the egg is heated, it solidifies and cannot be melted again.

Thermoplastics are long polymer chains that are fully polymerized when shipped by the resin manufacturer. Thermoplastics can be re-ground, melted and re-processed while retaining most of their original properties. An example of a natural thermoplastic material is wax. It can be melted and formed. Once cooled, the hardened wax can be melted and formed again. Unlike thermosets, most plastics companies prefer thermoplastic materials because they can be reprocessed and recycled.

Amorphous vs. Semi-Crystalline

Thermoplastic polymers can be categorized into two types; amorphous and semi-crystalline. Amorphous polymers melt gradually when heated. During cooling, amorphous polymer chains solidify slowly in a random orientation. By the end of the cooling phase, they shrink about 0.5%. Common amorphous polymers include ABS, polystyrene, polycarbonate, and PVC.

Semi-crystalline polymers melt quickly, once heated to their melting temperature. The rapidly melting polymer is easy to process compared to amorphous polymers. As a semi-crystalline material cools, portions of the polymer chains remain in a random state – while Semi-crystalline polymers melt quickly, once heated to their melting temperature. During cooling, semi-crystalline polymers shrink up to 3% — much more than amorphous polymers. Semi-crystalline polymers include acetal, nylon, polyester, polyethylene, and polypropylene.

Hygroscopic vs. Non-Hygroscopic

Thermoplastic polymers processed in the plastics industry are either hygroscopic; meaning they absorb moisture from the air, or non-hygroscopic; meaning they do not tend to absorb moisture from the air. Many low-cost commodity polymers, such as polypropylene, polyethylene, and polystyrene are non-hygroscopic polymers, which do not absorb moisture from the air. Any non-hygroscopic polymer can still get wet when exposed to water, or attract surface moisture in high humidity environments – such as outdoor silos, storage tanks, and overseas shipping containers.

Most engineering and specialty resins such as nylon, acetal, and polycarbonate are hygroscopic polymers, which absorb moisture from the air. These polymers have a natural attraction between the resin and water molecules. This creates a chemical bond, causing the polymer to retain water when it is exposed to moisture. In most cases, hygroscopic polymers require air which is both heated and dried to ensure proper material drying.

Hydrolysis is the breakdown of a water molecule when heated. Once broken down into hydrogen and hydroxide, these molecules will chemically react with the polymer chains, causing them to break. Visual defects such as splay, poor surface finish, bubbles, or delamination can occur as a result of moisture in hygroscopic polymers. Hydrolysis can also cause a significant change in the physical properties of the polymer including: reduced strength, increased brittleness, dimensional stability, poor heat resistance, and tendency to warp.

Viscosity

Viscosity is a measure of a material’s resistance to flow. A higher viscosity indicates a greater resistance to flow. Oil, for example, has greater viscosity than water. Typically, polymers with lower viscosity have low molecular weights. These materials are easier to process, but typically have less mechanical strength than a similar polymer having a higher melt viscosity.

Polymers are generally available in different grades, and each grade has particular flow characteristics. The viscosity of the polymer can be used to compare the flow characteristics of different polymers, or different grades of the same polymer. Viscosity data can also be used to qualify new materials by comparing a newer lot of material to a previously used material. Two of the most common methods of determining viscosity are Capillary Rheometry and Melt Flow Indexing.

Capillary Rheometry

Capillary Rheometry is an accurate method of measuring polymer viscosity. The polymer is usually tested at various temperatures and shear rates. When graphed, this data provides an accurate representation of the material’s processing behavior.

When comparing capillary rheometry data, try to compare the data at similar shear rates and temperatures. Although capillary rheometry data is preferred when comparing material flow characteristics, the testing process is time consuming. For this reason, capillary rheometry data is not readily available for all materials.

Melt Flow Index

Melt Flow Indexing is the most popular and least accurate method of determining material viscosity. This data is available for most materials and can be obtained from your material supplier.

The value obtained through the melt flow index test is a single data point, and tests the material at only one shear stress and one temperature. However, Melt flow index information from different materials and material grades may be used for a rough comparison of flow characteristics.

Plastic Materials Overview

Table of Plastic Material Properties

| Name | Grade | Spec. Grav. | Shrink % | D‑Temp °F (°C) | D‑Time (h) | Process °F (°C) |

|---|---|---|---|---|---|---|

| Acetal | Acetal | 1.39‑1.42 | 1.8‑2.2 | 175‑220 (80‑105) |

2‑3 | 370‑440 (190‑225) |

| Acrylic | PMMA | 1.08‑1.20 | 0.2‑0.6 | 150‑200 (65‑90) |

3‑6 | 350‑500 (175‑260) |

| Acrylonitrile Butadiene Styrene | ABS | 1.02‑1.05 | 0.4‑0.8 | 170‑200 (75‑95) |

2‑4 | 425‑500 (220‑260) |

| Chlorinated Polyvinylchloride | CPVC | 1.20‑1.30 | 0.5‑2.5 | 160‑180 (70‑80) |

1‑2 | 375‑435 (190‑225) |

| High Density Polyethylene | HDPE | 0.95‑0.96 | 1.5‑4.5 | 140‑160 (60‑70) |

1‑2 | 380‑550 (195‑290) |

| High Impact Polystyrene | HIPS | 1.04‑1.06 | 0.4‑0.8 | N/A | N/A | 410‑500 (210‑260) |

| Ionomer | Ionomer | 0.94‑0.98 | 0.4‑0.8 | 140‑175 (60‑80) |

2‑4 | 420‑530 (215‑275) |

| Linear Low Density Polyethylene | LLDPE | 0.91‑0.93 | 1.5‑4.5 | N/A | N/A | 325‑550 (165‑290) |

| Low Density Polyethylene | LDPE | 0.91‑0.93 | 1.5‑4.5 | N/A | N/A | 325‑550 (165‑290) |

| Nylon‑11 | Nylon‑11 | 1.04‑1.05 | 1.0‑2.0 | 150‑200 (65‑95) |

3‑4 | 440‑550 (225‑285) |

| Nylon‑12 | Nylon‑12 | 0.97‑1.06 | 0.6‑1.6 | 160‑200 (70‑95) |

3‑10 | 450‑570 (230‑300) |

| Nylon‑12/12 | Nylon‑12/12 | 1.06‑1.08 | 1.0‑1.5 | 160‑220 (70‑105) |

2‑4 | 500‑580 (260‑305) |

| Nylon‑4/6 | Nylon‑4/6 | 1.18‑1.21 | 1.6‑2.0 | 180‑220 (80‑105) |

2‑4 | 580‑600 (305‑315) |

| Nylon‑6 | Nylon‑6 | 1.10‑1.14 | 0.8‑1.5 | 150‑200 (65‑95) |

2‑6 | 460‑520 (240‑270) |

| Nylon‑6/10 | Nylon‑6/10 | 1.07‑1.08 | 1.0‑2.0 | 160‑200 (70‑95) |

2‑4 | 480‑550 (250‑290) |

| Nylon‑6/12 | Nylon‑6/12 | 1.03‑1.08 | 1.0‑1.5 | 150‑200 (65‑95) |

2‑4 | 450‑550 (230‑290) |

| Nylon‑6/6 | Nylon‑6/6 | 1.09‑1.14 | 1.0‑2.0 | 160‑220 (70‑105) |

2‑4 | 500‑580 (260‑305) |

| PC‑ABS Alloy | PC‑ABS | 1.10‑1.14 | 0.4‑0.8 | 180‑220 (80‑105) |

3‑5 | 480‑540 (250‑280) |

| PC‑PET Alloy | PC‑PET | 1.20‑1.22 | 0.6‑1.0 | 190‑230 (90‑110) |

3‑5 | 490‑550 (255‑290) |

| PC‑Polyester Alloy | PC‑Polyester | 1.18‑1.22 | 0.4‑1.0 | 190‑240 (90‑115) |

3‑5 | 480‑550 (250‑290) |

| Polyaryletherketone | PAEK | 1.37‑1.50 | 1.2‑1.6 | 300‑320 (150‑160) |

2‑10 | 700‑800 (370‑425) |

| Polybutylene Terephthalate | PBT | 1.30‑1.34 | 0.6‑2.0 | 200‑280 (95‑140) |

2‑5 | 450‑500 (230‑260) |

| Polycarbonate | PC | 1.15‑1.21 | 0.5‑0.8 | 240‑260 (115‑125) |

3‑5 | 500‑620 (260‑325) |

| Polyester | Polyester | 1.36‑1.40 | 1.5‑2.0 | 200‑270 (95‑130) |

3‑4 | 450‑510 (230‑265) |

| Polyetheretherketone | PEEK | 1.37‑1.50 | 1.0‑2.0 | 290‑310 (145‑155) |

2‑10 | 660‑750 (350‑400) |

| Polyetherimide | PEI | 1.27‑1.36 | 0.4‑0.7 | 250‑300 (120‑150) |

4‑6 | 640‑800 (340‑425) |

| Polyethersulfone | PES | 1.37‑1.50 | 0.8‑1.0 | 260‑300 (125‑150) |

2‑10 | 640‑730 (340‑385) |

| Polyethylene Terepthalate | PET | 1.25‑1.40 | 0.2‑0.5 | 250‑325 (120‑160) |

3‑6 | 480‑580 (250‑305) |

| Polyethylene Terepthalate Glycol | PETG | 1.25‑1.40 | 0.2‑0.5 | 150‑175 (65‑80) |

3‑6 | 300‑500 (150‑260) |

| Polyphenylene Oxide | PPO | 1.05‑1.10 | 0.5‑0.7 | 190‑240 (90‑115) |

2‑4 | 490‑590 (255‑310) |

| Polyphenylene Sulfide | PPS | 1.34‑1.40 | 1.0‑1.2 | 250‑320 (120‑160) |

2‑4 | 580‑640 (305‑340) |

| Polypropylene | PP | 0.89‑0.92 | 1.0‑2.0 | N/A | N/A | 390‑510 (200‑265) |

| Polystyrene | PS | 1.04‑1.06 | 0.3‑0.7 | N/A | N/A | 350‑525 (175‑275) |

| Polysulfone | PSU | 1.23‑1.25 | 0.4‑0.8 | 250‑300 (120‑150) |

4‑16 | 625‑725 (330‑385) |

| Polyurethane | PUR | 1.18‑1.20 | 0.4‑0.8 | 180‑280 (80‑140) |

4‑12 | 425‑525 (220‑275) |

| Polyvinylchoride | PVC | 1.20‑1.34 | 0.5‑2.5 | 160‑180 (70‑80) |

1‑2 | 330‑400 (165‑205) |

| Styrene Acrylonitrile | SAN | 1.07‑1.11 | 0.3‑0.7 | 160‑180 (70‑80) |

1‑2 | 420‑500 (215‑260) |

| Thermoplastic Elastomer | TPE | 0.90‑1.15 | 0.5‑2.0 | 150‑200 (65‑95) |

2‑4 | 350‑450 (175‑230) |

| Thermoplastic Elastomer Polyolefin | TPO | 0.91‑1.10 | 0.8‑2.0 | N/A | N/A | 375‑500 (190‑260) |

General Information About Common Materials

ABS (Acrylonitrile Butadiene Styrene)

| Trade Names | ABEL, ASTALAC, AVP, CEVIAN, CYCOLAC, ESPREE, EXCELLOY, KRALASTIC, LUSTRAN, Nyloy, Toyolac, TRILAC, Veroplas |

| General Characteristics | ABS is an amorphous terpolymer that consists of Acrylonitrile, Butadiene, and Styrene. This polymer has good flame retardant properties, a glossy finish, and high impact resistance depending on the blend. ABS has limited weathering resistance and certain grades have a relatively high cost. |

| Applications | General purpose, automotive, housings, electrical, and thin walled parts |

| Processing Temp. Range | 425-500 °F (220-260 °C) |

Acetal or POM (Polyoxymethylene)

| Trade Names | Celcon, Delrin, Hostaform, Kepital, Lucel, Lucet, RTP, Tarnoform, Tenac, Ultraform |

| General Characteristics | A highly crystalline polymer with good creep, fatigue, solvent, and water resistance. POM is a high strength and stiff polymer with good electrical properties. |

| Applications | Gears, bearings, automotive, and industrial |

| Processing Temp. Range | 375-420 °F (190-215 °C) |

Acrylic or PMMA (Polymethyl Methacrylate)

| Trade Names | Acrylite, Acryrex, Cyrex, Cyrolite, Kamax, Lustran, Optix, Plexiglas |

| General Characteristics | PMMA is a transparent amorphous thermoplastic low cost alternative to Polycarbonate when physical strength is not needed. This material also has better environmental stability than PS or PE, making it popular for many outdoor and automotive applications. |

| Applications | Automotive, TV Screens, Furniture, Windows, Medical |

| Processing Temp. Range | 350-500°F (175-260°C) |

CPVC (Chlorinated Polyvinylchloride)

| Trade Names | Harvel, Corzan, CTS, BlazeMaster, TempRite, Geon, Kaneka |

| General Characteristics | CPVC is an amorphous thermoplastic that is difficult to process due to very high shear sensitivity. Many grades of CPVC exist with different chlorine concentrations that effect the properties of the material. C PVC has strong chemical resistance with better temperature resistance than PVC. |

| Applications | Wire coating, tubing, automotive, electronics, profiles, drainage, and general purpose |

| Processing Temp. Range | 375-435°F (190-225°C) |

HDPE (High Density Polyethylene)

| Trade Names | Alathon, Bapolene, Braskem, Formolene, Ineos, SCLAIR |

| General Characteristics | HDPE is a highly crystalline opaque polymer with low moisture absorption as well as high tensile strength, chemical resistance and impact resistance. HDPE can also be machined and processed easily. |

| Applications | Automotive, coatings, containers, film, general purpose, industrial, packaging, tanks, and wire jacking |

| Processing Temp. Range | 380-550 °F (195-290 °C) |

HIPS (High Impact Polystyrene)

| Trade Names | ASTALAC, Avantra, CERTENE, Edistir, ESPREE, POLYREX, STYRON |

| General Characteristics | HIPS is an amorphous copolymer of Polystyrene and Polybutadiene rubber which has better impact resistance and dimensional stability than GPPS but lacks the superb clarity. HIPS has good machinability and dimensional stability with a low cost. As with GPPS, HIPS has poor solvent and electrical resistance. |

| Applications | Prototypes, housings, covers, toys, and appliances |

| Processing Temp. Range | 410-500 °F (210-260 °C) |

Ionomer

| Trade Names | Bexloy, Surlyn |

| General Characteristics | Ionomers are comprised of neutral and ionized polymer segments. Ionomers typically have ethylene based performance characteristics but with the added benefits of low temperature impact, chemical, and abrasion resistance. Some grades are designed to have high gloss and barrier properties. |

| Applications | Packaging, coatings, industrial, film, liners, sheet, and automotive exteriors |

| Processing Temp. Range | 420-530 °F (215-275 °C) |

LDPE (Low Density Polyethylene)

| Trade Names | Braskem, Kemcor, Lutene, Marlex, Riblene |

| General Characteristics | LDPE is a low cost, semi-crystalline polymer with good moisture resistance and flexibility. LDPE is generally used in high volume extrusion processes. |

| Applications | Agricultural, bags, coatings, containers, film, general purpose, packaging, and electrical insulation |

| Processing Temp. Range | 325-550 °F (165-290 °C) |

LLDPE (Linear Low Density Polyethylene)

| Trade Names | Braskem, CERTENE, DOW, Flexirene, NEO-ZEX, Petrothene, ULTZEX |

| General Characteristics | LLDPE is a semi-crystalline polymer with good moisture and chemical resistance. LLDPE typically has a rather high melt flow rate and exhibits good low temperature toughness and gloss. |

| Applications | Caps, containers, medical, toys |

| Processing Temp. Range | 325-550 °F (165-290 °C) |

PA-11 (Nylon-11)

| Trade Names | ASHLENE, Rilsan |

| General Characteristics | PA-11 is a semi-crystalline polyamide with outstanding thermal, chemical, and mechanical properties. PA-11 is a versatile polymer used in demanding situations due to its good impact properties and a high working temperature. |

| Applications | Hoses, electrical/electronics, automotive, sports, and medical |

| Processing Temp. Range | 440-550 °F (225-285 °C) |

PA-12 (Nylon-12)

| Trade Names | ASHLENE, Ecomass, Fostalon, Grilamid, PLUSTEK, Rilsan, Vestamid |

| General Characteristics | PA-12 is a semi-crystalline polyamide with great dimensional stability, impact strength, and chemical resistance. PA-12 is an excellent material for many applications because of its dimensional stability and properties at low temperatures. |

| Applications | Appliance components, automotive, bushings, cell phones, gears, general purpose, household goods, housings, medical, outdoor, engineering parts, sporting goods, tools, and wheels |

| Processing Temp. Range | 450-570 °F (230-300 °C) |

PA-4/6 (Nylon-4/6)

| Trade Names | Stanyl |

| General Characteristics | PA-4/6 is a semi-crystalline polyamide with outstanding structural performance properties and dimensional stability at elevated temperatures. PA-4/6 has excellent resistance to friction and wear with good flow properties. Many grades have some sort of fiber reinforcement to enhance the mechanical properties of the material. |

| Applications | Gears, automotive, electronics, and industrial |

| Processing Temp. Range | 580-600 °F (305-315 °C) |

PA-6 (Nylon-6)

| Trade Names | ALTECH, CAPRON, Durethan, Grilon, HiFill, Maxamid, Nypel, Radilon, Ultramid |

| General Characteristics | PA-6 is a semi-crystalline polyamide with great toughness and elasticity which makes it suitable for textile and oriented fibers. PA-6 also has high tensile strength and chemical resistance. |

| Applications | Textiles, fibers, zip fasteners, gears, gun frames, instrument strings, and surgical sutures |

| Processing Temp. Range | 460-520 °F (240-270 °C) |

PA-6/10 (Nylon-6/10)

| Trade Names | ALAMID, Nylene |

| General Characteristics | PA-6/10 is a semi-crystalline polyamide with a lower brittleness temperature, strength, and water absorption than other PA-6’s. PA-6/10 has good resistance to most solvents and diluted mineral acids. PA-6/10 tends to have large amount of shrinkage. |

| Applications | Electrical, filaments, and precision parts |

| Processing Temp. Range | 480-550 °F (250-290 °C) |

PA-6/12 (Nylon-6/12)

| Trade Names | ASHLENE, Nycal, Radici, Vestamid, Zytel |

| General Characteristics | PA-6/12 is a semi-crystalline polyamide with low water absorption compared to other nylons. PA-6/12 has more consistent properties than PA-6 when exposed to humidity and has good heat resistance and dimensional stability. |

| Applications | Electrical components, gears, general purpose, knife handles, gun frames |

| Processing Temp. Range | 450-550 °F (230-290 °C) |

PA-6/6 (Nylon-6/6)

| Trade Names | Celstran, Clariant Nylon 6/6, Elastoblend, HiFill, Nylene, Nymax, Polifil, Vydyne |

| General Characteristics | PA-6/6 is a semi-crystalline polyamide with good toughness and abrasion resistance. Typically used for commercial applications that will encounter extended use and abrasion. |

| Applications | Commercial grade fabrics, airbags, tires, textiles, carpets |

| Processing Temp. Range | 500-580 °F (260-305 °C) |

PAEK (Polyaryletherketone)

| Trade Names | Avaspire |

| General Characteristics | PAEK is a high performance semi-crystalline engineering thermoplastic that has extremely high temperature stability, mechanical strength, and chemical resistance. PAEK has slightly better dimensional stability and fatigue resistance than PEEK. |

| Applications | Chemical processing, electronics, medical, automotive, seals, valves, gears, and bearings |

| Processing Temp. Range | 700-800 °F (370-425 °C) |

PBT (Polybutylene Terephthalate)

| Trade Names | ABEL, ALCOM, ALTECH, ASHLENE, CELANEX, Crastin, Lutrel, PLANAC, POCAN, RAMSTER, Ultradur, VALOX, Vestodur |

| General Characteristics | PBT is a semi-crystalline polyester with good stiffness and toughness. PBT has similar properties to some nylons but with much less water absorption. PBT has a continuous service temperature of around 120°C and is often used as an electrical insulator. |

| Applications | Automotive, industrial, electronics, housings, medical |

| Processing Temp. Range | 450-500 °F (230-260 °C) |

PC (Polycarbonate)

| Trade Names | ALCOM, Apec, ASHLENE, CALIBRE, Carbotex, Durolon, Enviroplas, Hylex, LEXAN, Lupoy, Makrolon, Panlite, RAMTOUGH, TRIREX |

| General Characteristics | PC is an amorphous polymer with great impact resistance and optical clarity along with good heat resistance, toughness, and dimensional stability. Many polycarbonate products have surface coatings since PC does not have good chemical or scratch resistance. |

| Applications | Exterior automotive components, engineering components, housings, lenses, structural parts, medical components, and bullet proof sheeting |

| Processing Temp. Range | 500-620 °F (260-325 °C) |

PC/ABS (PC/ABS Alloy)

| Trade Names | Abel PC/ABS, ASTALOY, Bayblend, CYCLOY, Duroloy, EMERGE, EXCELLOY, Hybrid, Lupoy, Multilon, Novalloy-S, TECHNIACE, TRILOY, Verolloy, WONDERLOY |

| General Characteristics | PC/ABS is an amorphous thermoplastic copolymer of Polycarbonate and Acrylonitrile Butadiene Styrene. PC/ABS offers the properties of both PC and ABS including: the strength and heat resistance of PC and the flexibility of ABS. PC/ABS exhibits high toughness even at cold temperatures. |

| Applications | Automotive, electronics, medical, and aeronautical |

| Processing Temp. Range | 480-540 °F (250-280 °C) |

PC/PET (PC/PET Alloy)

| Trade Names | Makroblend, XENOY |

| General Characteristics | PC/PET is an amorphous thermoplastic blend that combines the properties of both PC and PET. It can be opaque or transparent and has high rigidity, dimensional stability, and impact resistance. |

| Applications | Sporting goods, electrical/electronic, automotive, industrial/mechanical, and household |

| Processing Temp. Range | 490-550 °F (255-290 °C) |

PEEK (Polyetheretherketone)

| Trade Names | Arlon, Ketaspire, MOTIS, PEEK-OPTIMA, VESTAKEEP, VICTREX |

| General Characteristics | PEEK is a high performance semi-crystalline engineering thermoplastic that has extremely high temperature stability and mechanical strength. PEEK has great dimensional stability, fatigue resistance, and chemical resistance with low smoke and toxic gas emission when exposed to flame. |

| Applications | Piston parts, gears, aerospace, automotive, chemical processing, and insulation |

| Processing Temp. Range | 660-750 °F (350-400 °C) |

PEI (Polyetherimide)

| Trade Names | ULTEM |

| General Characteristics | PEI is an amorphous polymer with excellent dimensional stability, chemical resistance, mechanical strength, and high temperature performance. PEI is electrically conductive which makes it suitable for some electronics applications. |

| Applications | Medical devices, microwave cookware, insulators, automotive, electrical/electronics, and metal replacement |

| Processing Temp. Range | 640-800 °F (340-425 °C) |

PES (Polyethersulfone)

| Trade Names | HiFill PES, Ratron, SUMIKAEXCEL, TRIBOCOMP, Ultrason |

| General Characteristics | PES is an amorphous transparent polymer with good stiffness and heat resistance. PES is suitable for high continuous use temperatures over extended periods of time. PES has high rigidity and dimensional stability over a broad temperature range. PES is susceptible to UV degradation and weathering. |

| Applications | Medical, automotive, industrial, pistons, filters/membranes, and electrical/electronics |

| Processing Temp. Range | 640-730 °F (340-385 °C) |

PET (Polyethylene Terepthalate)

| Trade Names | Ultrason, Valox, Hiloy, Impet, Petra, Shulandur, Ektar, Rynite, Selar, Dacron, Terylene |

| General Characteristics | PET is a semi-crystalline thermoplastic that is commonly used for synthetic polyester fibers and plastic bottle production. Most bottle manufacturers control the clarity of PET by limiting the degree of semi-crystallinity since higher levels of semi-crystallinity cause the product to turn opaque. PET has excellent chemical resistance and can withstand temperatures in excess of 212°F (100°C). |

| Applications | Bottles, fibers, synthetic fabrics, films, and packaging |

| Processing Temp. Range | 480-580°F (250-305°C) |

PETG (Polyethylene Terepthalate Glycol)

| Trade Names | Spectar, Vivak, Eastar |

| General Characteristics | PETG is an amomrphous thermoplastic which has similar properties to PET but with better mechanical and dimensional stability. PETG also has greater clarity and impact resistance than PET which makes it very popular for packaging applications such as thermoforming. |

| Applications | Fibers, films, and packaging |

| Processing Temp. Range | 300-500°F (150-260°C) |

PP (Polypropylene)

| Trade Names | Braskem, CERTENE, COPYLENE, Exelene, FERREX, Formolene, GAPEX, Hostacom, INEOS, Maxxam, Polifil, POLYFLAM, Pro-fax, RAMOFIN, TIPPLEN, YUPLENE |

| General Characteristics | PP is a versatile semi-crystalline polymer with high impact resistance and melt flow rates. PP is a resilient polymer that acts as a living hinge when cyclically loaded or fatigued. PP is difficult to bond with adhesives and has poor low temperature impact strength. |

| Applications | Automotive, films, containers, industrial applications, general purpose, and living hinge applications |

| Processing Temp. Range | 390-510 °F (200-265 °C) |

PPO (Polyphenylene Oxide)

| Trade Names | Fiberfil, Noryl |

| General Characteristics | PPO is an amorphous engineering plastic with high temperature resistance, dimensional stability, and electrical resistance along with low thermal expansion. PPO is sensitive to organic solvents and is susceptible to environmental stress cracking. |

| Applications | Pumps, valves, fittings, electrical components, manifolds, covers, housings, and coatings |

| Processing Temp. Range | 490-590 °F (255-310 °C) |

PS (Polystyrene)

| Trade Names | Amoco, Bapolan, Eporex, Styron, Valtra |

| General Characteristics | PS is an inexpensive amorphous polymer with great optical clarity. Unfilled polystyrene is typically called GPPS (general purpose polystyrene) and is rigid but brittle. PS can be used in virtually all processes, making it extremely versatile in the marketplace. PS has poor thermal stability and solvent resistance. |

| Applications | Toys, packaging, sheet, housings, appliances, household goods, and expanded beads |

| Processing Temp. Range | 350-525 °F (175-275 °C) |

PVC (Polyvinylchloride)

| Trade Names | APEX, Geon, Georgia Gulf, Manner, Reinier, Roscom, Sylvin, Unichem |

| General Characteristics | PVC is an amorphous thermoplastic that is difficult to process as a homopolymer. Many grades of PVC exist with different plasticizer concentrations that effect the processing of the material. Rigid PVC has strong chemical resistance and moderate temperature resistance. PVC has poor UV resistance. |

| Applications | Wire coating, tubing, automotive, electronics, profiles, general purpose, and medical |

| Processing Temp. Range | 330-400 °F (165-205 °C) |

SAN (Styrene Acrylonitrile)

| Trade Names | FORMPOLY, KIBISAN, Kumho, LG SAN, Lustran, Porene, SANREX, Veroplas |

| General Characteristics | SAN is an amorphous copolymer of styrene and acrylonitrile. SAN has higher strength, rigidity, and chemical resistance than polystyrene but lacks the same optical clarity. SAN has poor impact strength and low thermal capabilities. |

| Applications | Electrical, appliances, cosmetics, medical, containers, and automotive |

| Processing Temp. Range | 420-500 °F (215-260 °C) |

TPC-ET (Thermoplastic Copolyester Elastomers)

| Trade Names | Arnitel, Elitel, Hytrel, Keyflex, Riteflex |

| General Characteristics | TPC-ET polymers are amorphous thermoplastic copolymers that exhibit the flexibility of rubbers and the strength and processability of thermoplastics. TPC-ET blends have excellent flex fatigue resistance and a broad use temperature. They have good toughness and resist hydrocarbons. |

| Applications | Adhesives, cast film, coatings, filaments, hose, sheet, and tubing |

| Processing Temp. Range | 490-550 °F (255-290 °C) |

TPE (Thermoplastic Elastomer)

| Trade Names | Ecdel, Estamid, Estane, Hytrel, Kraton, Ontex |

| General Characteristics | A TPE is an amorphous copolymer of thermoplastic and elastomeric monomers and properties. TPEs can come in many classes including block-copolymers, polyolefin blends, and thermoplastic polyurethanes to name a few. Generally, these polymers have high heat resistance and ozone resistance. |

| Applications | Gaskets, automotive, sporting goods, tubing, and medical |

| Processing Temp. Range | 350-450 °F (175-230 °C) |

TPO (Thermoplastic Polyolefin)

| Trade Names | Exxtral, Lupol |

| General Characteristics | A TPO is a polymer/filler blend consisting of some fraction of polyolefin(s) and reinforcements. They have good dimensional stability and usually have a balance between stiffness and impact resistance in semi-structural and non-structural applications. |

| Applications | Appliances, automotive, electrical, consumer, packaging, and nonwovens |

| Processing Temp. Range | 375-500 °F (190-260 °C) |

PPS (Polyphenylene Sulfide)

| Trade Names | Fortron, Ryton, Sultron, TEDUR, Thermec, Xtel |

| General Characteristics | PPS is a semi-crystalline polymer which usually contains fillers or reinforcements. PPS has excellent ionizing radiation and chemical resistance. PPS is self-extinguishing and has low toxicity smoke when exposed to flame. |

| Applications | Chemical pumps, electrical components, coatings, piping, rods, and seals |

| Processing Temp. Range | 580-640 °F (305-340 °C) |

PSU (Polysulfone)

| Trade Names | Udel, Ultrason |

| General Characteristics | PSU is an amorphous polymer with good stiffness and heat resistance. PSU is transparent and maintains good mechanical properties over a wide temperature range. PSU has one of the highest service temperatures of melt-processable thermoplastics which can be autoclaved and steam sterilized without any loss in physical integrity. |

| Applications | Medical, electrical/electronics, filters, industrial, and aerospace |

| Processing Temp. Range | 625-725 °F (330-385°C) |

PUR (Polyurethane)

| Trade Names | Chronothane, Hydrothane, Polyblend |

| General Characteristics | PURs are a large family of polymers that may be thermoset or thermoplastic polymers with a broad array of properties. PUR has high abrasion resistance and is typically used as a coating, foam, or elastomer copolymer. These polymers tend to be weak to UV rays and most organic solvents. |

| Applications | Adhesives, bushings, coatings, insulation, piping, sealants, sheet, washers, and wheels |

| Processing Temp. Range | 425-525 °F (220-275 °C) |

Material Properties & Additives

Common Fillers and Fibers

Fillers and fibers are generally added to plastic materials to increase mechanical, chemical, or electrical properties as well as to reduce material costs in some cases. Reinforcing fibers such as carbon or glass are used to enhance mechanical properties while talc and clay are used as fillers.

Common Fillers and Fibers

Alumina |

Calcium Carbonate |

Carbon Black |

Clay |

Glass Bubbles |

Glass Fibers |

Graphite |

Quartz |

Talc |

Molydenum Disulfide |

Wollastonite Silicate |

|

|---|---|---|---|---|---|---|---|---|---|---|---|

| ABS | • | • | • | ||||||||

| Acetal | • | ||||||||||

| Acrylic | • | ||||||||||

| Nylon | • | • | • | • | • | • | • | ||||

| Polycarbonate | • | ||||||||||

| Polyester TP | • | ||||||||||

| Polyethylene | • | • | • | • | • | • | |||||

| Polypropylene | • | • | • | • | • | • | |||||

| Polystyrene | • | • | • | • | • | ||||||

| Polysulfone | • | ||||||||||

| Polyurethane | • | • | • | • | • | • | |||||

| PPO Modified | • | ||||||||||

| PVC (Rigid) | • | • | • | • | • | • | • | • | • |

Effect of Glass Fibers on Mechanical Properties

| ASTM D792 | ASTM D995 | ASTM D638 | ASTM D790 | ASTM D648 | ASTM D696 | |

|---|---|---|---|---|---|---|

| Specific Gravity | Shrink % | Tensile Strength kPsi (Mpa) |

Flexural Modulus kPsi (Mpa) |

Deflection Temp. 264 Psi (1.8MPa) °F (°C) |

Thermal Expansion % per °F (% per °C) |

|

| ABS | 1.05 | 0.6 | 6 (41) | 320 (2200) | 195 (91) | 0.0053 (0.0095) |

| 30% Glass | 1.28 | 0.1 | 14.5 (210) | 1100 (7600) | 220 (104) | 0.0016 (0.0029) |

| Acetal | 1.42 | 2.0 | 8.8 (60) | 400 (2800) | 230 (110) | 0.0045 (0.0081) |

| 30% Glass | 1.63 | 0.3 | 19.5 (134) | 1400 (9600) | 325 (163) | 0.0022 (0.0040) |

| Nylon 6 | 1.14 | 1.6 | 11.8 (81) | 400 (2800) | 167 (75) | 0.0046 (0.0083) |

| 30% Glass | 1.37 | 0.4 | 23 (158) | 1200 (8300) | 420 (216) | 0.0017 (0.0031) |

| Nylon 6/6 | 1.14 | 1.8 | 11.6 (80) | 410 (170) | 170 (77) | 0.0045 (0.0081) |

| 30% Glass | 1.37 | 0.4 | 26 (180) | 1300 (9000) | 490 (254) | 0.0018 (0.0032) |

| PPO | 1.06 | 0.5 | 9.5 (65) | 360 (2500) | 265 (129) | 0.0033 (0.0059) |

| 30% Glass | 1.27 | 0.2 | 21 (144) | 1300 (9000) | 310 (154) | 0.0014 (0.0025) |

| Polycarbonate | 1.2 | 0.6 | 9 (62) | 330 (2300) | 265 (129) | 0.0037 (0.0067) |

| 30% Glass | 1.43 | 0.1 | 18.5 (127) | 1200 (8300) | 300 (149) | 0.0013 (0.0023) |

| Polyester T.P. | 1.31 | 2.0 | 8.5 (59) | 340 (2300) | 130 (54) | 0.0053 (0.0095) |

| 30% Glass | 1.52 | 0.3. | 19.5 (134) | 1400 (9600) | 430 (221) | 0.0012 (0.0022) |

| HDPE | 0.95 | 2.0 | 2.6 (18) | 200 (1400) | 120 (49) | 0.0060 (0.0108) |

| 30% Glass | 1.17 | 0.3 | 10 (69) | 900 (6200) | 260 (127) | 0.0027 (0.0049) |

| Polypropylene | 0.91 | 1.8 | 4.9 (34) | 180 (1200) | 135 (57) | 0.0040 (0.0072) |

| 30% Glass | 1.13 | 0.4 | 9.8 (68) | 800 (5500) | 295 (146) | 0.0020 (0.0036) |

| Polystyrene | 1.07 | 0.4 | 7 (48) | 450 (3100) | 180 (82) | 0.0036 (0.0065) |

| 30% Glass | 1.28 | 0.1 | 13.5 (93) | 1300 (9000) | 215 (102) | 0.0019 (0.0034) |

| Polysulfone | 1.24 | 0.7 | 10 (69) | 400 (2800) | 340 (171) | 0.0031 (0.0056) |

| 30% Glass | 1.45 | 0.3 | 18 (124) | 1200 (8300) | 365 (185) | 0.0014 (0.0025) |

| SAN | 1.08 | 0.5 | 9.8 (68) | 500 (3400) | 200 (93) | 0.0034 (0.0061) |

| 30% Glass | 1.31 | 0.1 | 17.4 (120) | 1500 (10000) | 215 (102) | 0.0018 (0.0032) |

Heat Resistance

The safe continuous heat resistance temperature of plastics is an important factor in many applications. Although a polymer like PTFE has a high heat resistance temperature of 550°F it lacks most of its mechanical properties at that point. The following figure shows the continuous heat resistance temperatures of plastics but it does not necessarily mean the plastic will maintain optimal mechanical properties at that point.

Continuous Heat Resistant Temperature of Plastics

| °C | °F | |

|---|---|---|

| 316 | 600 | Most Plastic Materials Char or Burn |

| 302 | 575 | |

| 288 | 550 | PTFE |

| 274 | 525 | |

| 260 | 500 | Polyimide |

| 246 | 475 | |

| 232 | 450 | Phenolic Asbestos Filled |

| 218 | 425 | Silicone Mineral Filled |

| 204 | 400 | |

| 191 | 375 | PCTFE |

| 177 | 350 | |

| 163 | 325 | Polysulfone |

| 149 | 300 | Alkyds, Phenolics, Chlorinated Polyether |

| 135 | 275 | |

| 121 | 250 | Melamine, Nylon, Polypropylene, PPO, Polycarbonate |

| 107 | 225 | ABS/Polycarbonate Alloy |

| 93 | 200 | Acetal, ABS, Surlyn, Noryl, Polyurethane |

| 79 | 175 | Acrylics, Cellulosics, Polyethylene, Polystyrene, SAN, Vinyls |

| 66 | 150 | Urea |

| 52 | 125 | |

| 38 | 100 | |

| 24 | 75 | Room Temperature |

| 10 | 50 |

Hardness

The hardness of a plastic is usually recorded as a measure of the resistance of the material to indentation by a steel ball or point under load. The hardness is expressed as a number derived from the net increase in depth of the indentation during the hardness test. Since all plastics have unique characteristics, the observed hardness is a time dependent value which will change with the rate of loading.

Hardness of Common Plastic Materials

| Rockwell | Durometer | Barcol | ||

|---|---|---|---|---|

| M | R | Shore D | ||

| ABS | 85‑109 | |||

| Acetal | 94 | 120 | ||

| Acrylic | 85‑105 | 49 | ||

| Cellulosics | 30‑125 | |||

| PTFE | 50‑65 | |||

| PCTFE | 75‑95 | 76 | ||

| Ionomer | 60 | |||

| PPO | 78 | 119 | ||

| Nylon 66 | 108‑120 | |||

| Nylon 6 | 120 | |||

| Polycarbonate | 70 | 116 | ||

| Polyester Rigid | 65‑115 | 30‑50 | ||

| HDPE | 60‑70 | |||

| MDPE | 50‑60 | |||

| LDPE | 41‑46 | |||

| PP | 90‑110 | 75‑85 | ||

| GPPS | 68‑80 | |||

| Vinyl Rigid | 117 | 65‑85 | ||

| Vinyl Plasticized | 40‑100 Shore A |

|||

| Urea Cellulose | 110 | |||

| Silicone | 84 | |||

| Polysulfone | 69 | 120 | ||

| Polyester | 80 | |||

Burn Characteristics

Sometimes a plastic material is identified by its burn characteristics. The table below illustrates the various characteristics of plastics when ignited.

CAUTION: Any burn test should be done with the proper safety equipment and a ventilated hood.

Burn Characteristics of Plastics

| Material | Color | Odor | Speed |

|---|---|---|---|

| PE | Bright Blue Core | Paraffin | Fast |

| PP | Bright Blue Core | Acrid / Diesel fumes | Slow |

| PS | Yellow | Marigold | Fast |

| ABS | Yellow | Acrid | Slow |

| POM | Bluish | Formaldehyde | Slow |

| PA | Bluish | Burnt Hair | Slow |

| PC | Yellow | Phenol | Slow |

| CA | Greenish/ Yellow | Vinegar | Slow |

| PET | Yellow | Burnt Rubber | Fast |

| ABS/PC | Yellow | Acrid/Phenol | Slow |

| PVC-U | Greenish/ Yellow | Hydrochloric | Slow |

| PVC-P | Greenish/ Yellow | Hydrochloric | Slow |

Material Drying

Proper material handling and drying is critical to producing a consistent product with a reliable process.

Drying Terminology

Non-Hygroscopic Polymers

Many low-cost commodity polymers, such as polypropylene, polyethylene, and polystyrene are non-hygroscopic polymers, which do not absorb moisture from the air. Any non-hygroscopic polymer can still get wet when exposed to water, or attract surface moisture in high humidity environments — such as outdoor silos, storage tanks, and overseas shipping containers. Since water does not have a chemical bond to Non-Hygroscopic polymers, this moisture can easily be removed using forced hot air.

Hygroscopic Polymers

Resins such as nylon, acetal, and polycarbonate which absorb moisture from the air are called hygroscopic. These polymers have a natural attraction between the polymer and water molecules.

In most cases, hygroscopic polymers require air which is both heated and dried to ensure proper material drying. This air must have the moisture removed through a dehumidifying process, such as desiccant dryers or vacuum dryers.

Hydrolysis

Hydrolysis is the breakdown of a water molecule when heated. Once broken down into hydrogen and oxygen, these molecules will chemically react with the polymer chains, causing them to break. Visual defects such as splay, poor surface finish, bubbles, or delamination can occur as a result of moisture in Hygroscopic polymers.

Hydrolysis can also cause a significant change in the physical properties of the polymer including: reduced strength, increased brittleness, dimensional instability, poor heat resistance, and tendency to warp.

Relative Humidity

Humidity is a measure of how much moisture is present in the air. This is usually expressed as relative humidity, which is a percentage of how saturated with water the air is. For example, if the air is completely saturated and cannot hold any more water, it is represented as 100 percent humidity. The lower the air temperature, the less moisture air can hold.

Dewpoint

The point where the drop in air temperature results in 100% humidity is considered its dewpoint. This is the temperature where water will start to condense on most surfaces – including plastic pellets.

Therefore, a lower “dewpoint” value means the air is drier and will draw more moisture from the pellets.

Drying Procedures

Material drying specifications for hygroscopic materials are typically provided by the material supplier and are represented in both drying temperature and drying time. Additionally, your company may have specific drying temperatures and times that work best for certain grades of material.

The drying temperature refers to the temperature of the air being supplied from the dryer to the pellets. The drying time is typically provided as a range, such as 3 to 4 hours. This refers to the range of time the material can be exposed to the heated air provided by the dryer.

Comon Material Dryers

Material drying specifications for hygroscopic materials are typically provided by the material supplier and are represented in both drying temperature and drying time. Additionally, your company may have specific drying temperatures and times that work best for certain grades of material.

The drying temperature refers to the temperature of the air being supplied from the dryer to the pellets. The drying time is typically provided as a range, such as 3 to 4 hours. This refers to the range of time the material can be exposed to the heated air provided by the dryer.

Hot Air Dryer

The hot air dryer forces heated air though the pellets. These dryers heat the air using gas or electric heaters, and then force the hot air through the pellets using a blower fan. This method of drying is typically used to either remove surface moisture or preheat the polymer.

Compressed Air Dryer

The compressed air dryer uses air that is provided from an existing air compressor. The air passes through a heater before reaching the pellets.

At the compressor, the air loses moisture and the dewpoint typically drops 25 °C (45 °F) below the dewpoint of the ambient air within the room. This system typically takes 2 to 4 hours to completely dry and prepare a hygroscopic material for processing.

Desiccant Dryer

The desiccant dryer forces air that is both heated and dehumidified. The desiccant dryer uses a blower to draw cooled air from the hopper and forces the air through a moisture absorbing ‘desiccant bed’. After moisture is removed in the desiccant bed, the air is heated before reaching the pellets.

Since these dryers are capable of both heating and drying the air, they can significantly reduce the dewpoint. This dryer typically takes 2 to 4 hours to completely dry and prepare a hygroscopic material for processing.

Vacuum Dryer

The vacuum dryer functions on the same principle by which water boils. At typical atmospheric pressures, water will boil at 100 °C (212 °F).

The low pressures within vacuum dryers cause the water to boil at temperatures around 56 °C (133 °F), resulting in a faster drying time at lower temperatures. It is critical for each company to create its own material-specific procedures for vacuum drying.

PVC & CPVC Polymers

Definition of PVC

Polymers are large molecular chains made up of many smaller molecules. The word polymer can be broken up into two parts:

- Poly means “Many”

- Mer means ”Unit”

- Polymer means “Many Units”

A polymer consists of many smaller molecules called monomers. These monomers are combined into longer polymer chains. The process used to combine these molecules is called polymerization. In most cases, the longer the polymer chains, the tougher and stronger the polymer.

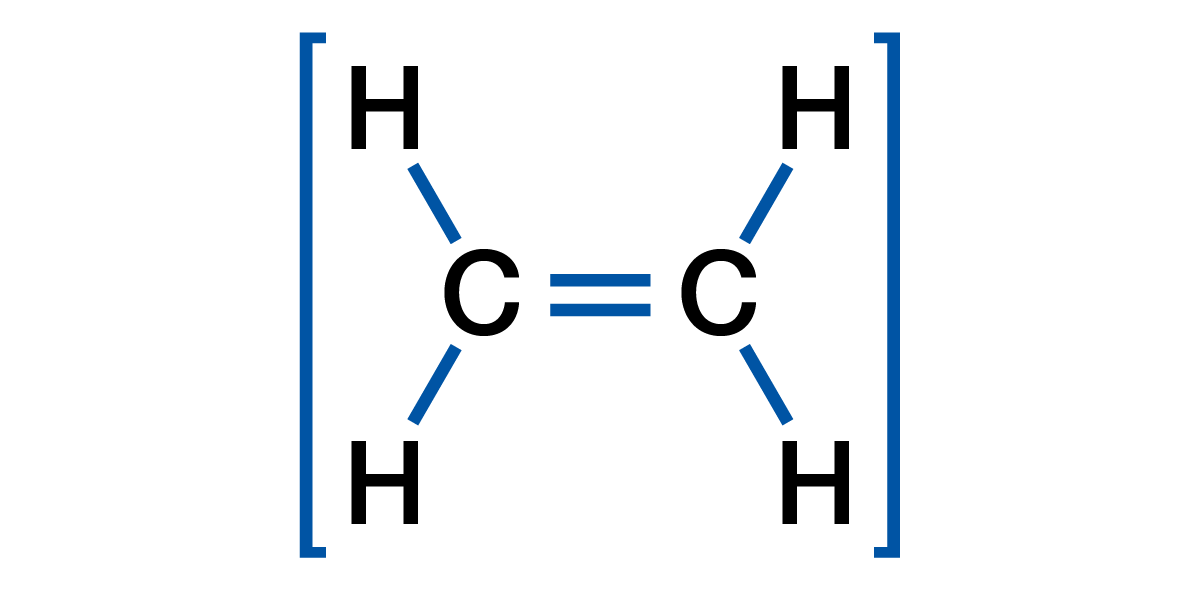

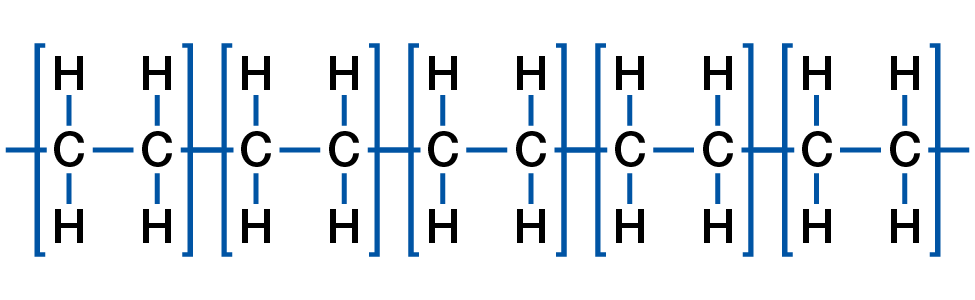

Polyethylene, for example, is one of the most commonly used polymers in the world. This polymer starts with an ethylene monomer of 2 carbons and 4 hydrogen atoms: When polymerized, Polyethylene is comprised of hundreds, thousands, or millions of repeating Ethylene units.

Smaller polyethylene chains (consisting of only hundreds of repeating units each) are often used for low strength applications, such as candle wax. Longer polymer chains make stronger polyethylene, which can be used for injection molding, extrusion, and blow molding processes.

Polyethylene, like all polymers, gets much of its strength from the entanglement of all these relatively long polymer chains. This strength is the highest when the polymer is cooled and the atoms are in a ‘low energy’ state where they are difficult to move around and untangle.

Ethylene Monomer

Polyethylene Polymer

PVC Polymer

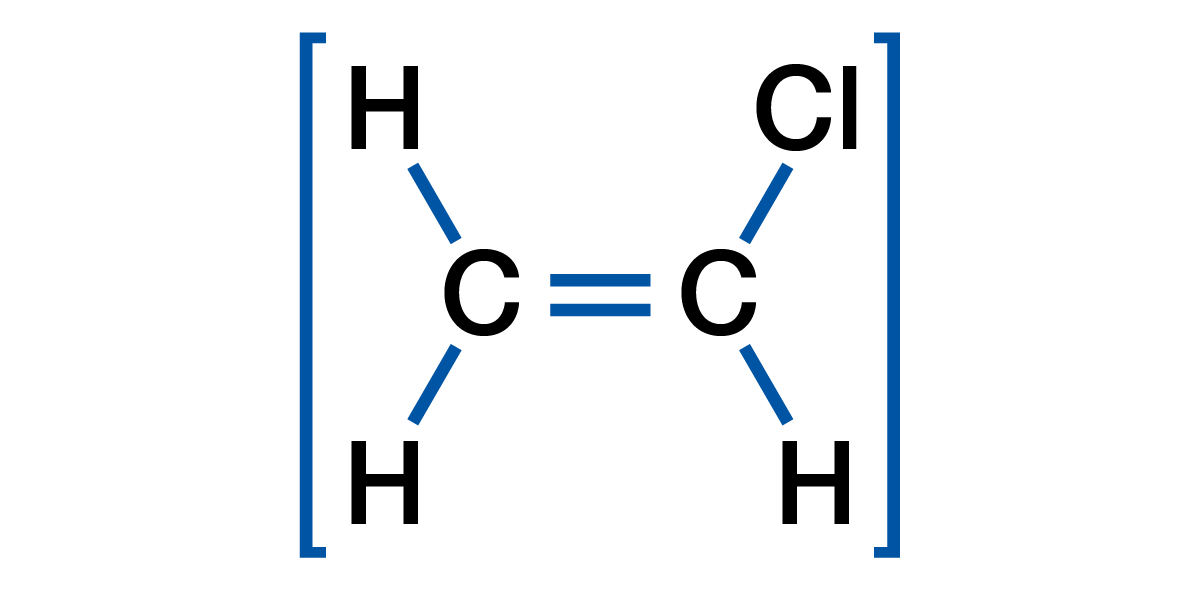

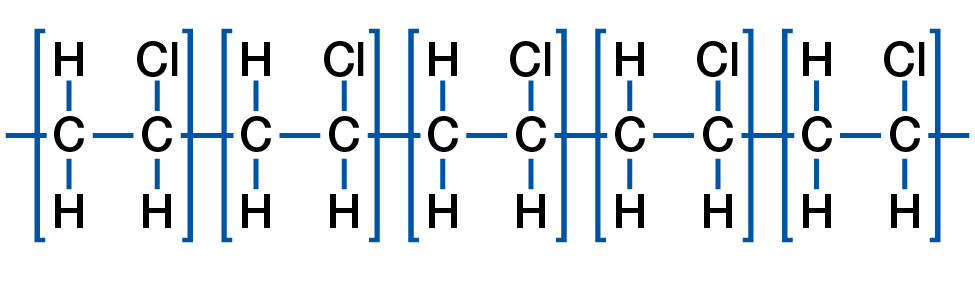

The Polyvinyl Chloride, or PVC, polymer starts with a monomer known as Vinyl Chloride. Vinyl Chloride is comprised of 2 Carbon, 3 Hydrogen, and 1 Chlorine atom.

When polymerized, the Vinyl Chloride monomer becomes the Polyvinyl Chloride polymer which is commonly known as PVC.

Vinyl Chloride Monomer

Polyvinyl Chloride Polymer

PVC gets very rigid when it cools, thus when these stiff PVC chains entangle, they gain a lot of strength. This chain entanglement contributes to much of PVC’s overall strength. The atoms on one polymer chain are also attracted to atoms on adjacent chains resulting in significant intermolecular attraction. The combination of rigid chains and intermolecular attraction cause the PVC polymer to be very hard and rigid. This rigidity makes PVC very difficult to process as the polymer chains will break if subjected to too much work and shear when melting or processing. Viscosity is a material’s resistance to flow, the higher the resistance to flow, the higher the viscosity. The rigidity of PVC causes the polymer to have a very high viscosity as compared to many other polymers.

The chlorine present on every unit of the PVC polymer chain causes material be less heat stable than most polymers during processing. When melt processing PVC, it is always important to avoid processing the material with too much heat or shear. When PVC degrades, one byproduct is chlorine gas, which is very dangerous and corrosive when not properly ventilated. The byproduct of degraded PVC will cause any PVC it comes in contact with to start degrading immediately. If excessive PVC degradation occurs, the result could be a cloud of chlorine gas or an explosion, both of which are very dangerous and potentially deadly. These gasses also contribute to the corrosion of metal surfaces such as the screw, barrel, die, and any exposed metal around the processing equipment.

When processed, PVC gives off a highly corrosive chlorine gas. This chlorine gas will accelerate rust, corrosion or oxidation on any surface it encounters including stainless steel. It is imperative that all exposed machinery and die surfaces are routinely cleaned, lubricated, or protected to prevent premature corrosion. There are also chlorine neutralizing sprays which can be used on the mold or die surfaces after processing PVC to reduce post-processing corrosion.

Chlorine and CPVC

PVC has good fire resistance, but the addition of chlorine to the PVC polymer chain will further increase the heat and fire resistance of the end product. Additional chlorine can be added through chlorination making a more rigid material known as Chlorinated Poly-Vinyl Chloride or CPVC. The extra chlorine increases chain rigidity and intermolecular attraction making the polymer very strong, rigid, and more difficult to process.

CPVC is challenging to process because it is much more rigid than PVC — with a much higher viscosity. CPVC is so rigid that it can be difficult to process without causing material degradation. For most of the remainder of this guide, PVC and CPVC will be used together as the concerns when processing the two materials are similar even though CPVC is more difficult to process.

Crosslinking of PVC or CPVC

The Vinyl Chloride monomer is turned into the PVC and CPVC polymer during polymerization. Most grades of PVC/CPVC will polymerize into long chain thermoplastic polymers.

Under the right conditions such as when degrading or when exposed to radiation, PVC and CPVC will cross-link. Crosslinked polymers are called thermoset polymers. These thermoset PVC/CPVC polymers are less common because they cannot be reground and re-processed. The remainder of this guide only focuses on the processing of Thermoplastic PVC/CPVC polymers and does not cover thermosets.

PVC & CPVC Components and Additives

Any additive, plasticizer, colorant, and heat stabilizer must be properly combined into a homogenous mix with the PVC or CPVC during processing or the material will not reach peak performance.

Fillers & Additives

Many different fillers and additives such as Talc, Calcium Carbonate, Sodium Sulfate, Glass Fibers, and colorants can be added for many reasons. Additives and fillers are introduced early in the polymer blending process. These could be added to reduce the cost of the material, increase the strength of the material, change the color, adjust the gloss, or even increase the density of the material.

Plasticizers

Due to the rigidity of PVC and CPVC, plasticizers are added during blending to help the polymer flow when processed. Large amounts of plasticizers are added when flexible PVC polymers are being blended. Plasticizers are usually comprised of smaller molecules which reduce the intermolecular entanglement or molecular attraction.

Rigid PVC and CPVC have a high viscosity because they use a minimal percentage of plasticizers to help flow, yet allow the final product to retain its stiffness. Rigid PVC and CPVC are commonly used for high strength applications such as plumbing pipes, pipe fittings, house siding, window frames, and control panels on ‘white goods’ such washing machines and dish washers.

Flexible PVC uses a much higher percentage of plasticizer to reduce the stiffness of the intended products. A further benefit of using a plasticizer is that it reduces the viscosity of the PVC. Common uses for flexible PVC are tubing, synthetic leather, shower curtains, films, and gaskets.

Heat Stabilizers

PVC and CPVC degrade very easily. Heat stabilizers are added during polymer blending to help reduce degradation and improve thermal stability when processing. The most common heat stabilizers are metal-based and often include multiple elements such as tin, barium, and calcium. These additives can withstand heat much better than PVC or CPVC alone, which improves thermal stability during processing.

PVC & CPVC Regrind

Thermoplastic polymers can be reground and re-processed, but PVC and CPVC can only be reprocessed until they degrade. When PVC or CPVC degrades, the degraded material will cause any PVC or CPVC molecules it encounters to degrade quickly due to a rapid chemical reaction. For this reason, you cannot put degraded PVC or CPVC back into the process or it will rapidly create more degraded PVC in the barrel and in your final product.

Since PVC and CPVC degrade easily, you must always be careful when processing regrind. Good quality PVC and CPVC regrind may have value as can be reprocessed. Good quality regrind refers to reground material which has no contamination or degradation.

Bad quality PVC or CPVC regrind has a negative value and will not only create more scrap in your process, but will also lead to more degraded PVC or CPVC. It is more cost effective to discard bad PVC or CPVC as processing degraded regrind material will lead to increased scrap and production losses. If your PVC or CPVC has degraded regrind in the mix, then it will create more degraded PVC in your final product. Degraded regrind or contamination will create a lower quality part which will likely have reduced properties such as poor strength, impact resistance, chemical resistance, and appearance. Processing degraded regrind will increase the chances that faulty product will reach your customers.

Performance vs. Non-Performance PVC & CPVC

Processing Performance PVC or CPVC

Performance PVC and performance CPVC refers to plastic used for functional applications such as pipes, fittings, siding, films, hoses, tubing, bottles, and window profiles. These products must meet specific performance requirements such as tensile, flexural, compressive, impact strength, and/or resistance to chemicals, UV, or radiation. The PVC or CPVC reaches peak performance when all the additives, plasticizers, heat stabilizers, etc. are thoroughly mixed which is a condition known as gelation or fusion.

Without proper gelation or fusion, the performance products may fail during use. It is common for performance products to meet all visual and dimensional requirements but fail when put through performance testing. This is often the result of inadequate gelation in the final product. Gelation and fusion will be covered in later sections of this guide, but general discussions related to Performance PVC/CPVC is covered below.

Performance polymers should be close to peak gelation or fusion at the end of the process to achieve the highest possible performance. When polymers reach peak gelation or fusion, the PVC or CPVC cannot accept much more time, temperature, or shear before the polymer begins to start degrading. For this reason, it is very difficult to process regrind made from performance PVCs. Regrind performance PVC or CPVC degrades easier than the virgin material in the pellet or powder forms because it has an additional time, temperature, and shear history. When regrind is incorporated in performance PVC and performance CPVC applications, the percentage used is often below 10% to prevent potential degraded material from causing significant performance losses. Waste material which does not show any signs of degradation such as burning, streaks, dieseling, or die lines is considered as usable regrind.

Documenting Performance PVC or CPVC

Essentially, the correct balance of time, temperature, and shear will help the PVC or CPVC fully mix and approach peak gelation or fusion. When the process makes acceptable product which meets all the visual and performance requirements, is it critical to fully document the process. This process documentation should include all the factors which go into making a good product. Specifics will be covered in later sections of this guide, but general documentation guidelines are covered below.

Machine, auxiliary, and downstream information should be recorded with any critical process information. Detailed process output data should be recorded as well as any information which helps identify what made good product during the specific production run. This includes the material lot, blending facility and equipment, pelletizing facility and line, percentage regrind, and any rheological information such as melt flow index, dryer residence time, barrel residence time, material temperature, coolant temperature, and any results from post-production testing including dimensional and gelation-related data.

Detailed process documentation should identify the factors which specifically relate to gelation or fusion such as all time, temperature, and shear factors. This way, the processor has information to help make process adjustments to compensate for time, temperature, and shear factors differences between one production run and another.

Proactive Process Adjustments

For performance PVC or CPVC applications, good process documentation allows the processor to make predictive adjustments based on an expected change in the time, temperature, and/or shear in an upcoming run. For example, if an upcoming production run is going to contain regrind, the barrel temperatures can be reduced to help mitigate the additional heat the regrind adds to the process. If a production run is scheduled to be run in a machine with a smaller barrel, the barrel temperatures or pressures might need to be increased to put more temperature or shear into the material – this can help compensate for the shorter time the PVC or CPVC will spend in the smaller barrel.

When using different equipment or material from run to run, a modified process may be necessary to get the same product performance. As a processor, you can control aspects of time, temperature, and shear on the PVC or CPVC, but many times it is the role of the processor to compensate for changes they cannot control such as a different machine or lot of material. The more a processor can predict these changes, the less scrap will be produced and the higher the production efficiency your process will have.

A proactive approach is important for performance PVC and CPVC applications. This is because most performance testing requires a specified time to pass such as 12 or 24 hours before the product can be properly tested. If a processor can gain some skill and experience in making effective proactive process adjustments, then it is often possible to run production while the product waits to be tested because there is a high-level of confidence that the product being produced will meet all quality parameters including performance testing.

Reactive Process Adjustments

The first use of this data is to make process adjustments on setting up, followed by adjustments after the product is found to be defective. If the PVC or CPVC shows degradation, then there needs to be a reduction in time, temperature, and/or shear such as a reduction in screw speed, barrel temperature, or a change to a machine with a smaller barrel. Conversely, if there is not enough gelation, then the time, temperature and/or shear applied to the material will need to be increased to get more gelation.

When using the same or similar processing equipment, the same process should be used to maintain the same balance of time, temperature, and shear. The part is likely to perform the same in testing, but good documentation will help you determine and compensate for differences during startup.

Keep in mind that many flexible PVC or CPVC applications can be considered performance PVC or performance CPVC applications if they must meet specific performance requirements such as chemical resistance or chemical characterization testing which require the PVC to be at near peak gelation or fusion to pass.

Non-Performance PVC Products

“Non-Performance” refers to non-functional applications such as decorative parts like panels, trim, and appliance panels. These products tend to have specific visual and fit requirements, but the PVC or CPVC does not have to perform at or near its peak strength or resistance capabilities.

These parts should always be processed with the minimal time, temperature, and shear necessary to make good product. This strategy provides the processor with a larger process window with the least likelihood of degrading the polymer. If the PVC or CPVC is processed at conditions significantly lower than necessary to achieve peak gelation, the defective products and waste can be reground and reprocessed with a lower risk of degradation.

As with Performance PVC and Performance CPVC applications, it is important to document all factors that make acceptable product, including all process outputs, material data, and time, temperature, and shear information. The positive aspect to non-performance PVC and non-performance CPVC is that you can usually match up the process outputs on similar processing equipment and the process should make good product. The detailed process documentation will help you identify and make efficient reactive adjustments when a significant change occurs in the time, temperature, and shear relationship such as degradation.

When using significantly different material grades and batches, or changing machinery from run to run, a proactive process adjustment should be considered before the process is started. This is recommended for non-performance PVC/CPVC applications to increase the efficiency of a production run. However, it is not typically as critical as it tends to be with performance PVC/CPVC products.

Time/Temperature/Shear Relationship for PVC & CPVC

Performance vs. Non-Performance

Performance PVC and Performance CPVC refers to polymers which must meet stringent strength or resistance properties. For the purpose of this guide, we will occasionally differentiate these polymers from non-performance PVC or non-performance CPVC polymers where the application may have specific appearance or dimensional requirements but does not have stringent performance requirements.

Gelation or Fusion

Once the polymer, additives, plasticizers, heat stabilizers, and other components in PVC or CPVC are fully mixed, the polymer is at peak strength. This is known as gelation or fusion because all of the components have become combined or fused into what is known as a gel. Full gelation or fusion refers to the point where the polymer matrix has fully formed, and it has achieved its optimal strength.

It is important to note that performance PVC/CPVC plastics are provided to the processor in a blended form, but all the components are not fully mixed when in pellet or powder form. This is because the process to properly combine all these elements puts excess heat and shear into the polymer. If this is all done before final processing, then the polymer will start to degrade once it is re-melted to processing temperatures. It is the job of the processor to complete the combining of the Rigid PVC or CPVC with the desired additives in the barrel. When done properly, the plastic in the final product has adequate gelation or fusion to achieve the desired properties.

Rigid PVC or CPVC products which have not reached full gelation or fusion will have reduced physical properties such as low impact, flexural, tensile, or compressive strength. These polymers which have low-strength will also have reduced resistance to attack from chemicals, UV rays, and electricity. Low gelation or fusion can cause product failures in the field such as bursting pipes, breaking fittings, cracked siding, leaking containers, or even food contamination.

The biggest problem the performance PVC or performance CPVC processor faces is when PVC or CPVC has not reached high gelation or fusion. In this instance, the plastic product may look good and meet the dimensional requirements and preliminary quality checks, but fail when the final product is tested for performance such as a pressure, strength, crush, flexural, impact, or chemical testing.

For performance PVC or CPVC to reach high gelation or fusion, a proper combination of time, temperature, and shear must be applied to the polymer. Gelation or fusion will not occur if there is too little time, temperature, or shear involved in processing. Unfortunately, when too much time, temperature, or shear is applied to the PVC or CPVC, it will begin to degrade. Good PVC and CPVC processing is based on understanding the proper balancing of time, temperature, and shear for your specific application.

In the Process Documentation portion of this guide, we’ll review how to document time, temperature, and shear on your process documentation.

Time

With respect to time, temperature, and shear for performance PVC or CPVC, time refers to the time the PVC or CPVC is exposed to heat and/or shear. To effectively combine all the polymer components and additives, both heat and shear must be applied over a period of time. Time examples include:

- Barrel Residence Time

How long the polymer remains in the barrel exposed to heat - Cycle Time

The time required to produce a fixed amount of product - Dryer Residence Time

How long the polymer remains in the dryer exposed to heat - Blending Time

How long the polymer is exposed to heat and shear during component blending

If any PVC or CPVC is exposed to heat or shear for an excessive amount of time, the polymer will begin to degrade. If performance PVC or CPVC is not exposed to heat or shear for enough time, insufficient gelation or fusion will occur, and the resulting product will not meet the end use requirements.

This time factor is very important to consider during production stoppages, slowdowns, shutdowns, startups, and changeovers as the polymer will begin to degrade. This is why it is very important to replace all the PVC with heat stable polymers immediately whenever the processing equipment is to be down or idle for any extended period of time.

Temperature

Temperature refers to the heat history applied to the PVC or CPVC. To effectively combine all the components, heat is a necessary factor. Without applying heat, the PVC and CPVC polymer chains would be too rigid to properly mix. Temperature examples include:

- Blender Temperature

- Barrel Zone Temperatures

- Die Temperatures

- Dryer Temperatures

- Coolant Temperatures

Temperature control is critical with PVC or CPVC. A temperature spike occurring anywhere during mixing, pelletization, drying, or processing can start the degradation process. To reduce heat generation, PVC or CPVC molding machines and extruders should use barrel heaters equipped with cooling fans. These fans circulate air around each barrel zone to prevent the material from overheating. In many instances, cored extruder screws cooled by air or oil mail may be used to help prevent overheating of the polymer during processing.

Shear

Shear refers to the work or mechanical energy applied to the PVC or CPVC. To effectively combine all the components, shear is a necessary factor as the polymer must be thoroughly mixed. Examples of when PVC or CPVC is sheared include:

- Material mixing and blending

- Pelletization

- Screw rotation and screw geometry, features and characteristics

- Back pressure in the extruder caused by the breaker plate, filters, die head, or die

- Material flow through the extruder, die, or mold

- Restrictions or blockages in the extruder, die, or mold

With PVC or CPVC, shear creates significant heat. Always be very careful whenever adding shear to a PVC or CPVC process. Adding both energy and heat can bring the material to the point of degradation very quickly.

PVC or CPVC Gelation or Fusion

The point where PVC or CPVC approaches peak mixing of components is called gelation or fusion. When gelation occurs, the PVC or CPVC polymer has the highest strength, impact resistance, chemical resistance, heat resistance, fire resistance, and UV resistance. Gelation is critical for high performance PVC or CPVC products such as pipes, fittings, containers, siding, window casings, and medical tubing.

Incomplete or non-gelation - Many parts look good after processing but have not reached gelation resulting in lower mechanical and resistance properties. In most cases where performance is critical, insufficient gelation or fusion will often result in parts failing during use.

Non-gelation is generally acceptable for applications such as appliance panels, decorative components, and other low-risk applications where fit and appearance is more important than performance.

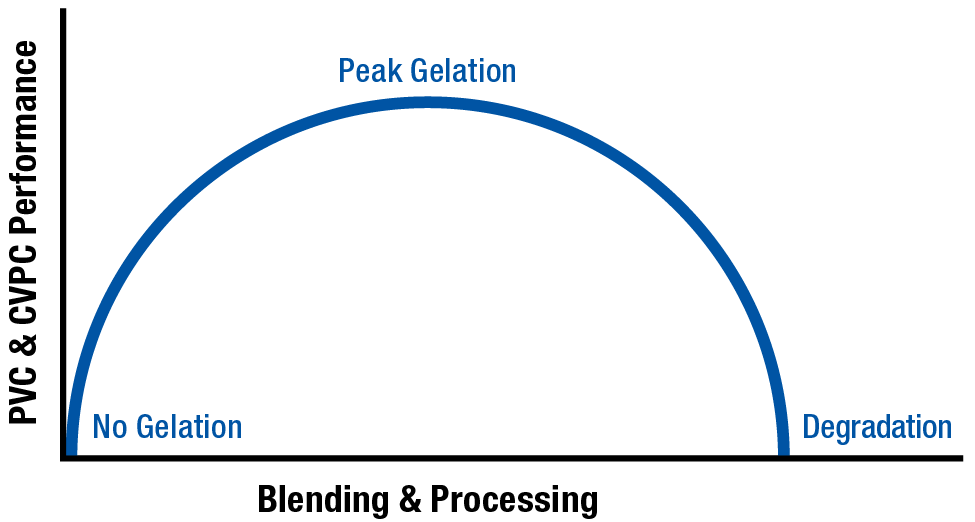

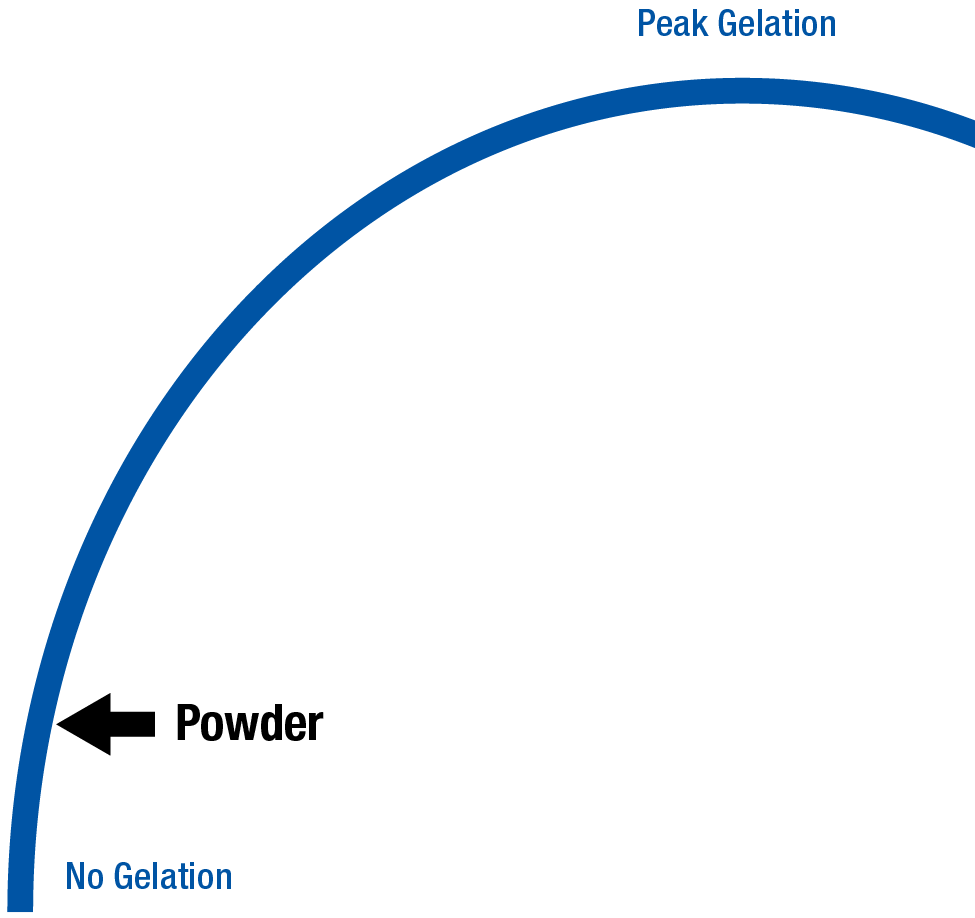

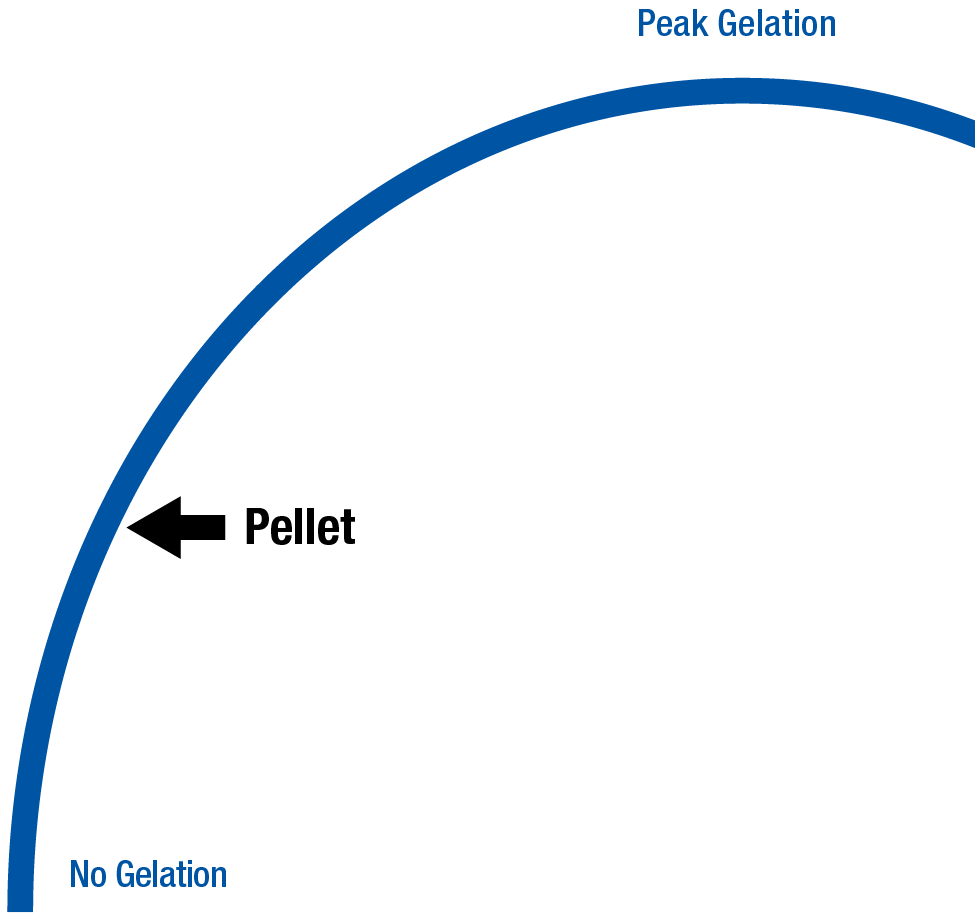

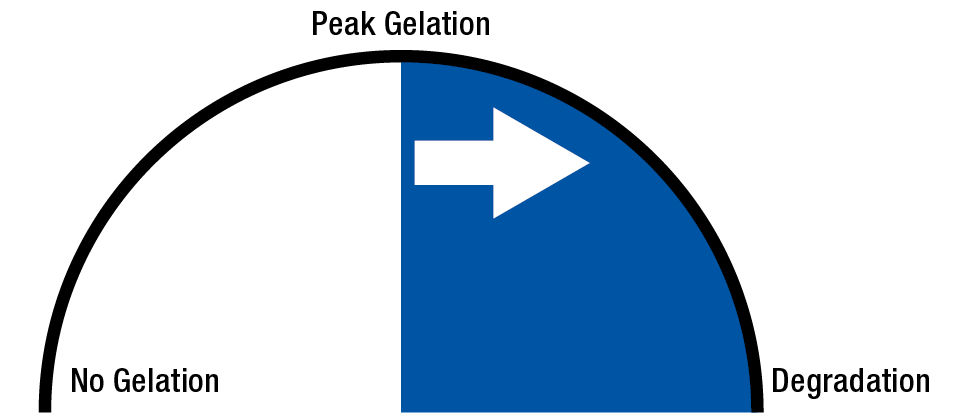

The figure below shows the starting state of polymer with the lowest strength at ‘No Gelation’. Once the polymer starts receiving a time, temperature, and shear history the strength of the polymer increases with corresponding increase in gelation or fusion. Once too much time, temperature, or shear is applied, the PVC or CPVC will start to degrade resulting in a loss in polymer properties the more it degrades.

PVC or CPVC Arc of Gelation or Fusion

PVC Degradation

Once a high level of gelation or fusion is achieved, additional time, temperature, or shear will begin the degradation process. Once PVC or CPVC begins to degrade, it undergoes a chain reaction which accelerates more degradation of adjacent PVC chains.

This degradation chain reaction is a primary reason why it’s critical that all PVC or CPVC processing equipment is streamlined: without any gaps or hang-up points where the polymer flow can stop. If the PVC or CPVC stagnates at any point, the stagnated polymer will degrade — in turn, causing all polymer that touches it to degrade.

This degradation is often seen in extrusion in situations where degraded PVC/CPVC is present inside or on the edge the extrusion die. This will cause a continuous brown stripe in the extrudate until the degraded material is removed from the die. Another example of this is degraded material in the nozzle of an injection molding machine. This degraded PVC or CPVC will cause brown streaks on the gate area of the molded parts on every cycle until the process is stopped and the nozzle is properly cleared of degraded material.

Excessive PVC degradation is very dangerous. As mentioned before, polymer chains degrade in a rapid, continuous reaction. Toxic chlorine gas can be produced rapidly and the polymer chains can crosslink and seize the screw inside the barrel. PVC or CPVC cannot be left in the barrel for any extended period of time. Rather, it must be replaced with a heat stable material, such as a Polyolefin (PE or PP) or Purging Compound.

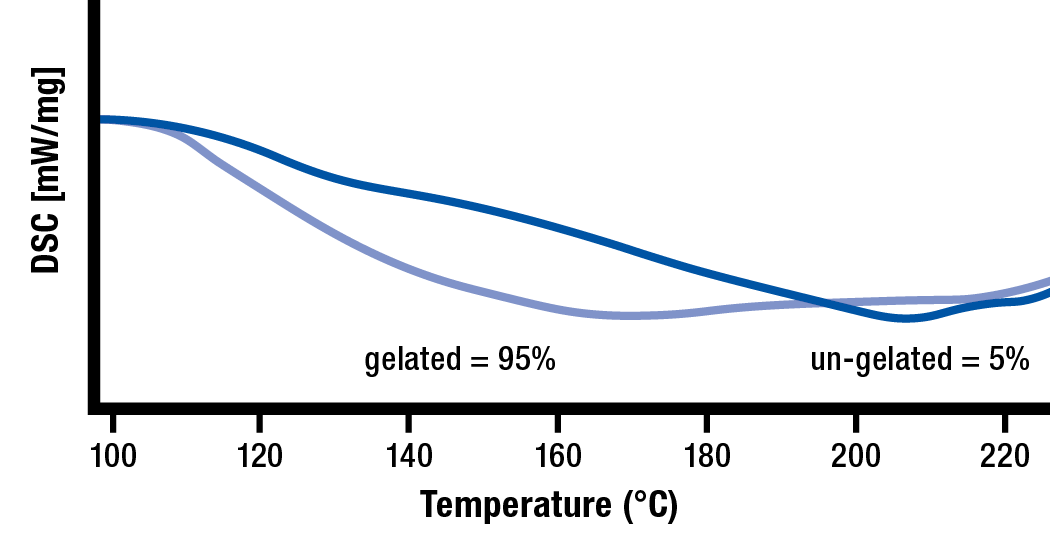

Testing of Gelation or Fusion of PVC & CPVC

The only way to know the amount of gelation or fusion in your PVC or CPVC after being processed is to conduct a test on the material using one of the following tests. All the tests in this section apply to testing of the final product. In all cases, the final product testing is destructive, thus you will not be able to sell the product after gelation or fusion is tested.

Chemical Immersion Test

In this test, the PVC is immersed in a chemical for a pre-determined amount of time to visually evaluate the amount of damage the chemical does to the polymer. To conduct this test, the PVC or CPVC sample is cut at an angle to help expose a large amount of internal surface area to the chemical. The internal surface of the PVC must be exposed for this test to provide accurate results because the outer surfaces tend to develop a skin which may resist chemical attack.

For example, ASTM D2152-17 entitled ‘Standard Test Method for Adequacy of Fusion of Extruded Poly (Vinyl Chloride) (PVC) Pipe and Molded Fittings by Acetone Immersion’ uses product which is cut and submersed in acetone for a specified period of time.

If the processed PVC or CPVC have a high amount of gelation or fusion, the PVC or CPVC will show no signs of attack at the end of this chemical immersion test. This means the product has passed the test and is likely to have good strength and resistance properties due to a high degree of gelation or fusion.

If the PVC or CPVC sample shows discoloration, pitting, streaking, or any noticeable change in appearance, the polymer components have not been properly mixed, or some degradation has begun to occur. In either case, the polymer matrix does not have enough gelation or fusion.

The chemical immersion test is a common general test for gelation or fusion because poorly gelated PVC or CPVC will be easily attacked. This is because all the components have not been blended into a cohesive polymer matrix.

The challenge with this test is that the person evaluating the results must have the necessary experience to evaluate minor attacks on the PVC or CPVC. The results of this test are generally considered pass or fail, but an experienced technician can provide a subjective evaluation on the degree of attack and type of damage which has been done to the sample by the chemical.

Aside from Pass or Fail, the results of this test are not quantitative, but observational data can be helpful to the technician – for example, pitting in the tested sample might indicate poor mixing while streaking in the sample may indicate degraded polymer.

The general methodology of the chemical immersion test is straightforward:

- The test sample is prepared by cutting it with an angle to expose the internal polymer

- The area of the sample being tested is submerged into the chemical for a period of time

- The sample is removed and chemical is washed off to make the sample safe to handle

- The exposed polymer is visually inspected to determine whether the polymer passed or failed

Advantages & Disadvantages

There are several advantages and disadvantages associated with using the Chemical Immersion Test to evaluate the gelation or fusion of PVC and CPVC materials.

Advantages:

- Many chemicals are available for use in this test

- Testing is easy to perform

- Cost is low

Disadvantages:

- The test takes a significant amount of time to complete

- The chemicals used can be very dangerous

- Proper PPE and ventilation are required

- Evaluation requires training and experience

- Evaluation of results are very subjective

- Test results are not quantitative

Impact Strength Test

In this test, the PVC or CPVC is subjected to a high-speed impact of a specific weight moving at a specific speed which is measured as energy. In some tests, the sample breaks and the loss of energy is measured. In other tests, the sample is tested at a specific energy level to determine if it will break or not. This is a pass/fail test. With respect to PVC or CPVC, the better the part performs in testing, the more gelation is likely present in the product.

Pendulum Impact Strength Test

The most common form of impact strength test is the pendulum test. In this test, a weighted pendulum is swung through the test sample to break it. The pendulum starts on one side of the testing apparatus from a fixed point and the highest position of the pendulum’s upswing is measured. This measurement corresponds to the amount of energy lost as the pendulum passed through the sample. The less the pendulum swings afterward, the more energy has been lost during the breaking of the sample. In theory, properly gelated product will have a higher energy loss when being tested than low gelation product does.

Different tests may use different weights and methods for holding the sample. For example, ASTM D2560-10 titled ‘Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics’ uses a notched sample which is struck while clamped in a vertical orientation.

The general methodology of different pendulum impact testers is common:

- The test sample is prepared by cutting it to size and often is notched to reduce the effects of the outer polymer skin from skewing the test results

- The sample is secured in the testing apparatus

- The swinging weight is lifted and released from a fixed point

- The energy loss is measured

Falling Weight Impact Strength Test

The falling weight impact test is a simple way to test the impact resistance of a product. These tests use a weight with a piercing element which is dropped from a specific height. The test is designed to determine whether the product resists puncture in a pass or fail evaluation. The energy used in the test is created by the dropping of the weight in the test. In most cases, the product has a specific weight and height impact that it is designed to resist. When the test is designed properly, a well-produced and gelated PVC or CPVC product will pass this test by resisting puncture, while poorly manufactured product will fail the test. Different tests use different weights and points for puncturing the sample. In many applications, the final product is fixtured under the falling weight. This tests how a product will perform when impacted by something realistic such as a hammer.

Different tests may use different weights and methods for holding the sample. For example, ASTM D5420-21 titled ‘Standard Test Method for Impact Resistance of Flat, Rigid Plastic Specimen by Means of a Striker Impacted by a Falling Weight (Gardner Impact)’ offers different product geometries, weights, and heights for standardized testing.

The general methodology of falling weight impact testers is common:

- The test sample is prepared by cutting it to size (where applicable)

- The cut sample or finished device is secured in the testing apparatus

- The falling weight is lifted and released from a fixed height

- The sample either passes or fails the test based on whether the product is punctured